Products

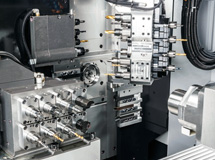

- CNC Precision Automatic Lathe

-

The long-term stable production is realized by tool configuration to minimize the thermal displacement and high-rigid casting base to prevent vibration at high-speed machining.

Spindles suitable for long, short, or heavy-duty cutting can be selected, and TSUGAMI's guide-bushless enables accurate machining with economical materials.

Best for mass production of high-precision small components, such as parts for office automation (OA) equipment, medical equipment, digital camera, cellular phone, optical communications, and automobiles.

- CNC Lathe

-

Powerful turning machine with turret tool post and rigid machine structure

Ideal for machining parts for automobiles and construction equipment

A wide variety of machines are available, from basic machine to turning center with back spindle and Y axis.

It allows users to select the most suitable machine for machining complex workpieces, regardless of bar or chucker.

Automation system is supported with the optional NC loader and work

stocker system.

- Turning Center

-

Multi-tasking turning center that integrates turning and machining operations

Turning Center can meet the needs such as:

the number of live tools is insufficient, machining that used to be done with lathe and machining center needs to be consolidated into one, and multiple workpieces need to be machined without setup changes.

Valuable to machine the complex-shaped components in the fields such as the automobile and aircraft industries, as well as in the medical and jewelry industries.

- Machining Center

-

Series of machining centers for various machining purposes, from small aluminum parts for IT-related applications including home appliances and OA equipment, to iron-based automotive parts and industrial machinery parts.

Worthful not only for drilling, tapping but for milling.

Contributes to high-speed / accurate machining and improved productivity by minimizing the displacement in machining dimensions as the operation time passes.

- Precision Grinding Machine

-

TSUGAMI grinding machine has earned a high reputation for stable accuracy and durability by the wheelhead spindle with hydrodynamic bearings and V-flat guide with uniform contact face finished by scraper.

The machine can handle from raw materials to hardened steel, ceramics, and small and medium-sized components.

In addition, it responds to customers' needs from single piece products such as mold pins, small volume components such as engine, transmission, hydraulic equipment, IT-related, and medical equipment, to high-volume production of fully automated machining systems by the auto loaders and automatic measurement.

- Precision Thread and Form Rolling Machine

-

A plastic forming machine to transcribe the shape of the pair of the rolling die driven by hydraulic power or servo to the workpieces.

Unlike cutting and grinding, no chips are generated, and this processing method also draws attention from an environmental protection perspective.

With CNC control, a single machine can perform rolling at multiple positions, and realizes integration of processes. (R7NC, R17NC-Ⅱ)

In addition to thread or knurling, high accuracy lead screws, worms, and forming are possible.

Independent opposed gang tool post

Independent opposed gang tool post Opposed gang tool post

Opposed gang tool post Gang tool post & turret

Gang tool post & turret Precision gang tool post

Precision gang tool post Vertical gang tool post

Vertical gang tool post Turret

Turret Bar work

Bar work Bar work & chuck work

Bar work & chuck work Vertical machining center

Vertical machining center Horizontal machining center

Horizontal machining center CNC precision cylindrical grinding machine

CNC precision cylindrical grinding machine Small precision grinding machine

Small precision grinding machine Carbide tool grinding machine

Carbide tool grinding machine CNC precision thread and form rolling machine

CNC precision thread and form rolling machine Precision thread and form rolling machine

Precision thread and form rolling machine